Cold Storage for the Winery

Cold storage can be such an amazingly valuable tool for the winery and growers.

While on the vine grapes are naturally protected from microbes such as yeast and bacteria. Once they are picked time is of the essence to cut down on exposure, which is why most growers pick in the early morning hours (or even at night under lights). Assuming everything goes according to plan the fruit will be delivered to the winery, get processed, and end in a fermentation vat while still cold. But, in the world of wine grapes and the winery – things often do not go according to plan. This is where cold storage can save the day.

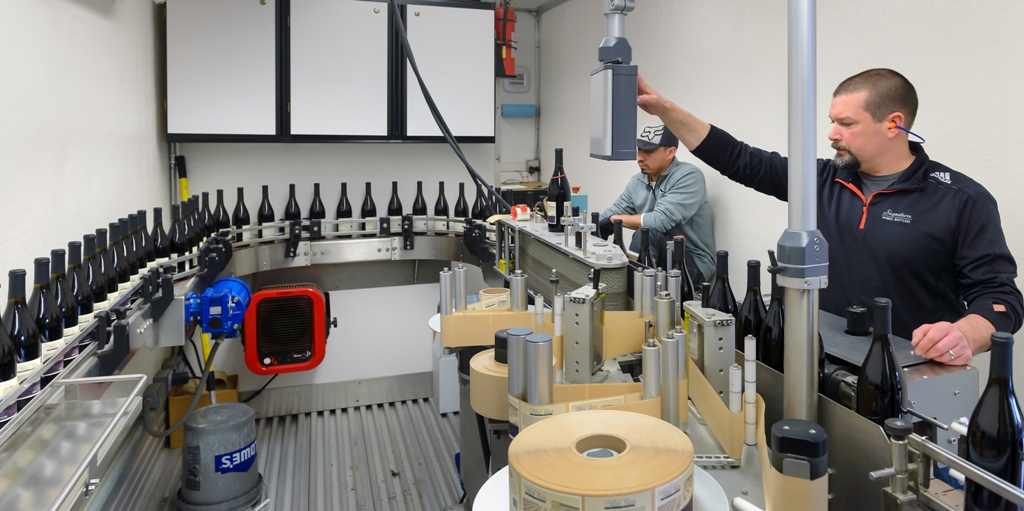

Grapes undergo the sorting process better when they are cold. This is because the fruit is denser, allowing the berries to stay more intact throughout the sorting and destemming process. This is especially crucial for quality reds, like Pinot Noir, when the winemaker wants the grapes whole and intact as it can lend to more fruitiness and limit harsh tannin extraction. High-end sorting equipment, such as the optical sorter we have at Naumes Crush, also works better with whole berries.

Most often with red winemaking, the winemaker will want to keep the must in the fermentation vat cold for a period of time prior to the fermentation. This is called a “cold soak.” If the fruit arrives at the winery warmer than ideal, not only will the destemming and sorting be less effective, but attempting to cool down the must and hold it cold is very difficult, thereby shortening the duration or limiting the cold soak option altogether.

Cold storage can buy the winemaker time. Cold storage can chill the grapes for better processing and cold soaks.

As a custom crush facility, coordinating with the clients and their picking crews can be very challenging. Especially if there is a rain event on the forecast and lots of fruit needs to come off the vines. Utilizing cold storage, all picks can be received and tucked away into cold storage and processed within a day or two, while resulting in higher quality destemming, sorting and cold soaking. This also results in better logistical flow, planning and better quality of wines across the board. Naumes Crush also offers cold storage for growers and other wineries so they may benefit from these advantages as well. Growers will find it very useful for consolidating picks over time to a single shipment. Wineries can buy time if they need to pick grapes but aren’t ready to process.

Indeed, cold storage is an incredibly valuable tool for the wine industry, and Naumes Crush hopes to elevate the quality of wines in the valley by offering this tool to its clients, as well as other growers and wineries in Southern Oregon. Please contact us if you have any questions about our cold storage options and availability for your winery.

Chris Graves; Winemaker